Most good animal handlers know people , not machinery, make the job easier.

“You can spend all the money in the world on facilities, but if the cattle are fighting (the handling), you’ve got a challenge,” said Dylan Biggs of TK Ranch near Coronation, Alta.

The art of tearless handling is slowly coming to more ranches, but Biggs still meets many skeptics who do not believe one man can make a herd work for him. He said it is all a matter of paying attention to animals’ behaviour and movement patterns.

Read Also

More work wanted on removing red tape

REGINA — Canadian farmers risk falling further behind competitors if two main federal agencies don’t become more efficient and responsive…

After growing up on a traditional ranch where processing cattle was a nightmare the family dreaded, he decided to find a better way.

“I got sick and tired of the force, the fear, using pipes, prods, hockey sticks and yelling. I got tired of fighting with cattle.”

Biggs studied with Bud Williams, the guru of cattle handling. He admits it took several years to master what Williams seemed to do so easily. Now he runs on-farm clinics to share the message.

Patience and understanding are the keys, he said.

“The reason it works for us is because the cattle work for us.”

He and his wife Colleen or their hired man can move their 300 cows or a herd of yearlings with little fuss. It does not take more time and animals do not necessarily have to be tame to be persuaded to co-operate.

The work starts in the pasture. If cattle were frightened there, that anxiety continues when they are taken home for sorting and doctoring.

“Ninety percent of the problems in the corrals are a result of what happened in the pasture.”

His ranch’s corrals are probably 60 years old, but he does recommend getting a good squeeze.

“Spend your money on a good squeeze. People get hurt with poor squeezes.”

The best system gently squeezes the animal on both sides rather than pushing it into a V-shape where it could lose its footing.

A cow held on both sides can still get out without difficulty if it goes down.

The squeeze should also be quiet.

As well, Biggs’ unit has a cement floor because animals need good footing.

“A poor floor can really scare cattle coming in.”

Frightened animals can pile up. People then lose their patience and pandemonium results.

“It’s amazing what goes on out there and how western it gets.”

Colorado State University animal behaviourist Temple Grandin has preached the same message throughout her career.

In her lectures and published work, she emphasizes the need to understand livestock psychology and to combine that understanding with well-designed facilities that reduce stress for people and animals.

People need to realize cattle have poor depth perception when they are moving with their heads up. To see depth, they have to stop and put their heads down. This is why they balk at shadows, glaring lights and unfamiliar objects on the ground.

Even a discarded styrofoam coffee cup can cause distress.

If the lead animal refuses to move, a pile up can ensue.

Because cattle also balk if the chute appears to be a dead end, they need to be able to see through them. However, palpation gates should be solid so cattle do not see the person standing in the chute.

Curved chutes are better because they do not appear to be a dead end and the animals cannot see the people or trucks ahead of them.

Tim O’Byrne of Calico Beef Consulting agrees that the human factor overrides everything else.

O’Byrne teaches livestock handling and trucking courses.

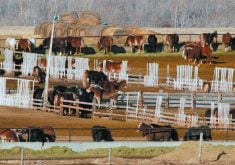

He sees potential for people problems in high-throughput facilities like feedlots and packing houses.

People may be required to work eight to 10 hours per day for six weeks handling one hydraulic chute. Up to 800 head per day could move through that chute.

Accidents are lessened if the process is done properly, but lots of noise and fuss can turn it into a stressful event for man and beast. Animals also start to consider the noise an irritant and ignore the commands.

“Vocals should be a prompt. A lot of screaming and whooping going on is a total misuse of a prompt,” O’Byrne said.

Many large facilities now keep motors for hydraulic chutes outside the work area, try to minimize banging noises, and position people carefully. Blinds and louvers can block distractions so animals move quietly rather than bunching up and trampling one another.

Changing systems requires a commitment from everybody involved.

“Everybody needs to stop and realize they are entering a cattle environment and adopt certain rules.”

The high turnover in hired help is another challenge.

“We design a fantastic facility with senior level handlers in mind and within two years the crew is made up of entry level experience.”

Entry level workers needs protection as well as heightened awareness of animal welfare, O’Byrne said.

It doesn’t do any good for a company to make a large investment in mechanical facilities, but forget to train its people properly.