KAMLOOPS, B.C. – The cattle business has to beef up its product if it expects to remain the meat of choice in the future.

Those attending the Canadian Cattlemen’s Association convention here were invited to share an industry vision that will devote more effort to producing a top quality commodity.

The industry may be enjoying almost unimpeded access to the American market and some success in Japan, producers heard, but everyone agreed there are quality issues to address.

Tenderness is at the top of the checklist for product improvement. Tough meat is unacceptable and the complaint level of 20 to 30 percent dissatisfaction among customers is too high, said executive vice-president Dennis Laycraft.

Read Also

More work wanted on removing red tape

REGINA — Canadian farmers risk falling further behind competitors if two main federal agencies don’t become more efficient and responsive…

“We have not driven the value equation as far as the pork or poultry industry,” he said.

The packing industry has jumped on the bandwagon to make a good product better. Brent Altwasser, plant operations manager of Lakeside Packers in Brooks, Alta., said recent attitude changes in beef production are reflected in the profit picture.

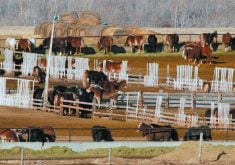

This year Lakeside has been averaging 75 to 100 loads of beef carcass shipments to the United States each week as Canada’s reputation for quality grows.

Room to improve

But there’s plenty of room for improvement, he said. Problems that start in the pasture continue to the packer level.

Hides scarred by branding lowers leather value. Although more hides are coming in with no brands, so they can rate as higher-priced “native hides”, Altwasser said he still sees too many rib or multiple brands.

On the meat side, fewer condemned livers are appearing. Packers appreciate that because it’s difficult to remove a bad liver without contaminating other organs. About $20 is lost when an abscessed liver has to be disposed of, he said.

“You can really tell a lot, standing at the gut table, how the cattle have been fed,” he said, noting high-energy diets can cause abscesses.

In the last three years a vast reduction in injection site injuries has been noted at Lakeside. Up to 25 pounds of meat may be cut away because of damaged and infected tissue when immunizations or antibiotics were given improperly, Altwasser said. This could cost $50 to $75 per carcass.

With the help of animal behaviorist Temple Grandin, Lakeside has changed its operations to reduce bruising as animals move through pens and chutes.

“Bruising is more extensive than it needs to be,” he said. All bruised muscle is cut away, which is a further loss.

Altwasser also warned that some people don’t pay enough attention to withdrawal times from medication before sending animals for slaughter. Agriculture Canada randomly inspects for chemical and antibiotic residues. If inspectors see injection site damage the carcass is automatically set aside for tissue samples. There is a 24-hour response test and a 72-hour confirmation test before the carcass goes any further.

A new concept called Hazard Analysis Critical Control Points has emerged from food poisoning episodes at American Jack-In-the Box restaurants several years ago.

Using HACCP guidelines, packers are moving from visual inspection to microbiological standards, where all traces of manure and mud must be gone.

Research has shown these contaminants are prime hosts for E. coli bacteria which can cause fatal illness.

Stricter rules are also coming for handling downer cattle, those that can’t move on their own.

Agriculture Canada is circulating a proposal that downers can’t be transported until examined by a vet. Cattle down on arrival at a plant will also be inspected. If the vet decides an animal went down before it got on the truck, an investigation will result.

“We see too many cattle coming that should never have been sent to the plant,” Altwasser said.